Cases

STWMF has over 60 years of experience in the design and production of can making lines and related equipment. We have supplied high-quality can making machines for customers all over the world. For example, our electromagnetic ovens have been sold in Germany. Automatic hot water circulating sterilization systems have been sold in Russia. Automatic can body welding machines are sold all across Europe, the Middle East, Russia, India, Latin America, Africa, and Southeast Asia. Our equipment has a service life of around 15 years.

We have established long-term cooperative relationships thanks to quality products and good service.

Case 1Time: July, 2016

Country: Dubai

Customer: Tomato paste manufacturing company

- Complete solution from tomato paste can making to can filling.

- Two lines: 180 cans/min for 153 and 99 mm (diameter) cans, 500 cans/min for 73 and 52 mm (diameter) cans.

- We provided a complete can production line and can filling equipment.

- Whole period: 6 months

- Shipped at Shantou Port

- On-site installation and debugging free of charge, 1 month

- As of July of 2018, 100 million tinplate cans have been produced

- One time normal maintenance on site

Time: June, 2014

Country: Jordan

Customer: Tinplate printing and can making factory

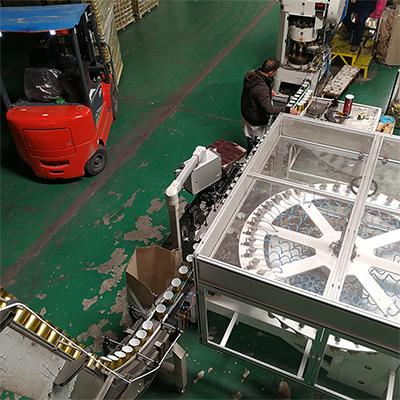

- Completecan production line: slitter, welder, spray machine, powder spray machine, drying machine, combination machine of necker, flanger and beader, seaming machine.

- Four lines: 80 cans/min for 153 mm (diameter) cans, 280 cans/min for 99 mm (diameter) cans, 350 cans/min for 73 mm (diameter) cans, 60 cans/min for 215 mm (diameter) cans

- We provided complete standard lines in batch, 3 months per batch

- Shipped at Shantou Port

- On-site installation and debugging free of charge, 15 days

- Hundreds of millions of cans have been produced;

- Normal maintenance every 2 years; On-site maintenance + remote operations (remote program input, video)