-

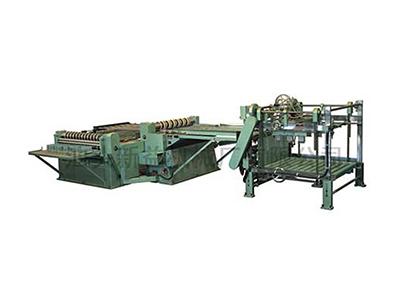

- Gang Slitter The ST-B2B gang slitter features a duplex slitting function, making it an important device for early stage production. The tin plate is first cut into a strip using the round cutter according to the desired size...

-

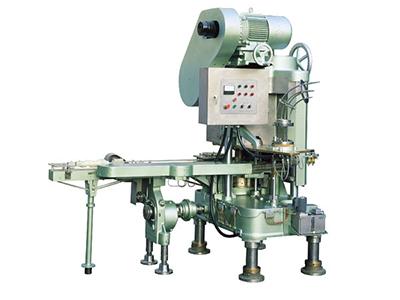

- Automatic Can body Welder The can body welder, also called a tinplate welding machine or can bodies welder, is the heart of any 3 piece can production line as it forms the body blanks into their basic shape, then welds the seam overlap.

-

- Automatic Inside Spray Machine The automatic inside spray machine is used for an effective welding seam protection both can interior and exteriors. In a 3 piece can, the welding seam must be protected after can body welding to avoid corrosion or oxidation...

-

- In-line Can Leakage Tester STWMF’s in-line can leakage tester, also called a metal can leak tester or in-line leak testing machine, is used for can quality testing. It is designed to quickly detect any can leakage so that all qualified products enter into the next process...

-

- Flanger/Necker/Beader During can production processes, a modeling treatment is required after can body welding, making later can seaming convenient, and improving the can’s appearance. Common modeling processes include flanging, beading and necking.

-

- Can Seamers STWMF produces a variety of can seamers used for seaming food and beverage inside cans after filling. We offer automatic can seaming machines, as well as equipment that combines seaming, flanging, and beading into a single equipment piece.

-

- Water Spray/Steaming Sterilizer STWMF water spray retorts are made of stainless steel and are equipped with an imported specialized computer and automatic recorder. This allows the water spray retorts to precisely control and record the full sterilization process...

-

- Sterilization Retort STWMF provides a variety of sterilization retorts for sterilization before can filling processes, including both vertical and horizontal sterilizers.

-

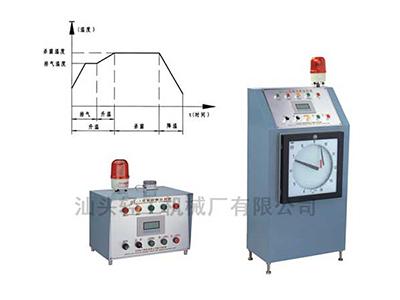

- Retort Control System The automatic retort control system features automatic control for exhausting, heating, and sterilization stages inside the retort by using a PLC system to strictly control the steam valve and exhaust process. Recording is completed automatically.

- Home

- Products

Products

STWMF specializes in the design and assembly of can production lines and related equipment, including gang slitters, canbody welders, inside spray machines, can leakage testers, flangers, neckers, beaders, and can seamers.