- Home

- Metal packaging solution

- Three-piece Can Production Line

Three-piece Can Production Line

The most commonly used cans are three-piece sanitary cans which consist of a body and two end pieces that are joined together to provide a hermetic, or perfect, seal. Most commonly used for foods that are heat processed they are also used for packaging powders, syrups, and many other products that are not heat-processed. The most common shape is a round cylinder but square and oval flat cans are used, particularly for seafood processing.

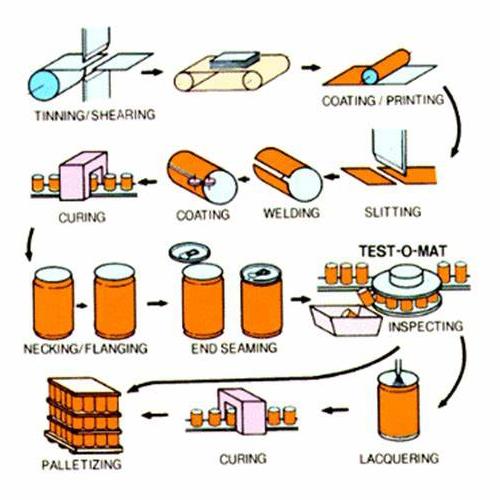

Major metallic packages made of tinplate include can bodies, basic shells (BS), easy-open ends (EOE), metal crown lids, twist-off lug caps, metal rings, and EOE ring tabs. Common empty cans include three-piece cans for beverages, DI steel cans, DRD cans, spray cans, 18-liter cans, and irregular cans, of which three-piece cans are the most important empty can type. The production process of three-piece cans includes slitting, body rounding, welding, striping and capping. Although the process is complicated, a can-body combined machine can complete all the production steps with ease.

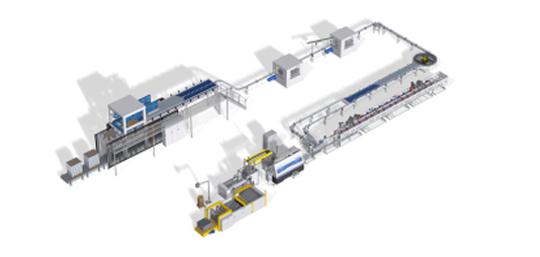

An automatic empty-can production line is made up of a can-body combined machine, a two-way slitter, a welder, weld joint protection stripping/curing system, an internal spraying/curing system (optional), an inline detecting machine, an empty-can stacking machine, strapping machine, and wrapping/shrink packaging machine. Currently, a can-body combined machine can complete can-making steps such as slitting, necking, swelling, flanging, beading, first seaming, and second seaming at a maximum speed of 500 CPM.

Three-Piece Can Manufacturing Process:Feeding → slitting (slitter) → can body rounding (automatic canbody welder) → weld joint striping (spraying and drying equipment) →capping (seamer)

Milk Powder Tin Can

Milk Powder Tin Can Beverage Cans

Beverage Cans Cosmetic Cans

Cosmetic Cans Food Tin Can

Food Tin Can Tinplate Aerosol spray tin

Tinplate Aerosol spray tin Chemical Cans

Chemical Cans Paint Can

Paint Can Irregular Cans

Irregular Cans