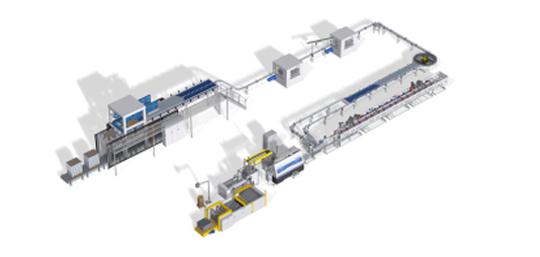

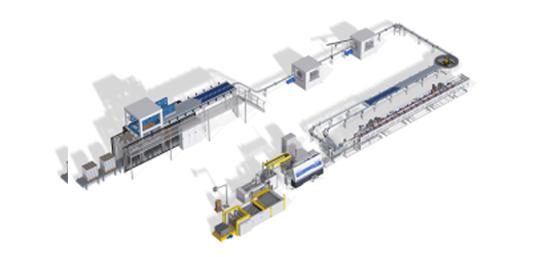

Typically, a production system has six separate stations: a slitter to cut the tinplate base material into body blanks of the required size; a transfer system to feed the cut blanks from the slitters to the canbody welder. A welding unit to shape and weld the canbody. a seam protection system to prevent oxidation and chemical reactions damaging the welded can. A curing system to dry and harden the seam protection. And a body former (to give the canbody its final profile and shape). A single control system, equipped with a touchscreen panel, is used for central operation and control of the entire production line.

-

- Gang Slitter STWMF offers gang slitters for cut of tinplate or aluminium sheets.ST-B2B gang slitter, with duplex slitting function, is an important device in the early stage.

-

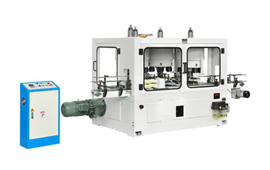

- Automatic Can body Welder The can body welder, also called a tinplate welding machine or can bodies welder, is the heart of any 3 piece can production line as it forms the body blanks into their basic shape, then welds the seam overlap.

-

- Automatic Inside Spray Machine The automatic inside spray machine is used for an effective welding seam protection both can interior and exteriors. In a 3 piece can, the welding seam must be protected after can body welding to avoid corrosion ...

-

- In-line Can Leakage Tester STWMF’s in-line can leakage tester, also called a metal can leak tester or in-line leak testing machine, is used for can quality testing. It is designed to quickly detect any can leakage so that all qualified products enter into the next process...

-

- Flanger/Necker/Beader During can production processes, a modeling treatment is required after can body welding, making later can seaming convenient, and improving the can’s appearance. Common modeling processes include flanging, beading and necking.

-

- Can Seamers STWMF produces a variety of can seamers used for seaming food and beverage inside cans after filling. We offer automatic can seaming machines, as well as equipment that combines seaming, flanging, and beading into a single equipment piece.

-

- Water Spray/Steaming Sterilizer STWMF water spray retorts are made of stainless steel and are equipped with an imported specialized computer and automatic recorder. This allows the water spray retorts to precisely control and record the full sterilization process...Generally horizontal design is adopted to increase water spray area, improving working efficiency.

-

- Sterilization Retort STWMF’s GT7C3 vertical sterilizer is suitable for the sterilization of packaging cans used in canned, bottled or soft packaged food industries. It is also suitable for pharmaceutical, textile, bamboo, and wood product industries.