- Home

- Products

- Can Body Making Machine

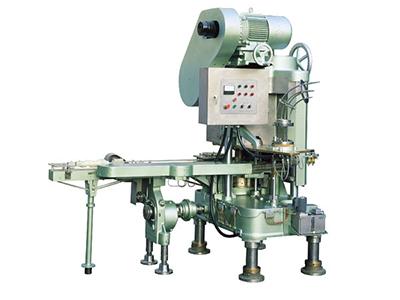

- Automatic Inside Spray Machine

Automatic Inside Spray Machine

The automatic inside spray machine is used for an effective welding seam protection both can interior and exteriors. In a 3 piece can, the welding seam must be protected after can body welding to avoid corrosion or oxidation, as any environment change inside the cans will affect the food’s shelf life.

STWMF’s automatic inside spray machine is suitable for the spraying protection of cans containing highly corrosive contents such as highly acidic beverages, as well as can making processes in which the can body’s inner coating is damaged and needs to be resprayed. It is a specialized can production machine and can be used in conjunction with our can body welders to ensure the can sealing performance and separate materials inside from the can, ensuring an outstanding can body and welding seam corrosion resistance.

STWMF provides customized inside spray machines according to all system configurations, production speed and can size. They feature a simple operation, clean spray, and a low paint or powder consumption.

Parameters| Spray guns number | Production capacity | Can diameter | Can height | Compressed air |

| 2 | 300 cans/min | 52-85 mm | 45-200 mm | 5 kg/cm2 |