-

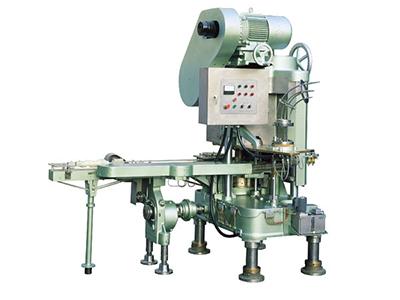

- Automatic Vertical Flanging Machine The ST-B14VY automatic vertical flanging machine is suitable for the flanging of round 3-piece cans with diameter of 202-401D. It is widely used in different scale can production factories.

-

- Automatic Vertical Can Body Necking Machine The ST-B31VA automatic vertical can body necking machine is used for the necking of large and round 3-piece cans. It will neck welded can bodies according to set proportions. Depending on different can sizes, it features a production capacity of up to 350 cans/min.

-

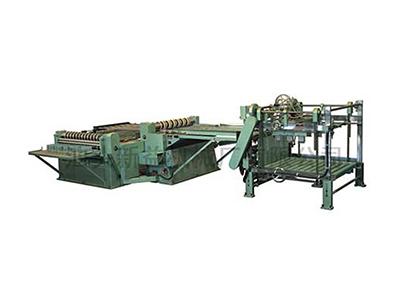

- Automatic Vertical Flanger with Beader The automatic vertical flanger with beader is designed for the flanging and beading of large 3-piece cans. Featuring a vertical design, STWMF’s automatic flanger with beader features a small footprint, making hit easy to connect to automatic seaming machines after the beading process.

-

- Automatic Vertical Necker with Flanger Machine Automatic vertical neckers with flanger machines are used for the necking and flanging of large 3-piece cans to form various shapes. STWMF supplies a variety of independent neckers and flangers, as well as combination machines.

- Home

- Products

- Can Body Making Machine

- Flanger/Necker/Beader

Flanger/Necker/Beader

During can production processes, a modeling treatment is required after can body welding, making later can seaming convenient, and improving the can’s appearance. Common modeling processes include flanging, beading and necking.

Flanging is convenient for later can seaming, and beading is used to roll the can body and form a reinforcement ring to improve the can’s strength. It is suitable for large cans, including milk powder cans.

Necking is most commonly used, as it will neck the can body based on a set ratio to produce cans in a variety of shapes.

STWMF has over 60 years of experience in can production equipment, and we offer high-quality flanging, beading and necking equipment. We also produce single-function equipment such as automatic flangers, automatic beaders and automatic neckers. Moreover, we can also provide multiple function combination machines suitable for a variety of large and medium can manufacturers. We also provide customization service according to your requirements to help customers save costs associated with purchasing several devices.