- Home

- Products

- Can Body Making Machine

- Flanger/Necker/Beader

- Automatic Vertical Flanger with Beader

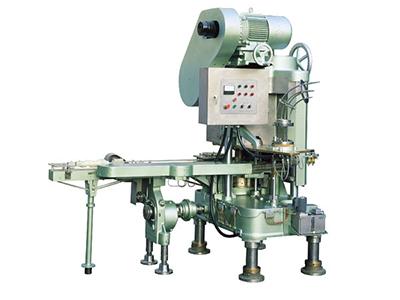

Automatic Vertical Flanger with Beader

The automatic vertical flanger with beader is designed for the flanging and beading of large 3-piece cans. Featuring a vertical design, STWMF’s automatic flanger with beader features a small footprint, making hit easy to connect to automatic seaming machines after the beading process.

STWMF provides three flanger with beaders models, of which the ST-B64A product is also equipped with a necking function. All of our products use inverters to control the speed, making mass production easy and efficient.

Advantages- Back plate type or double roller beading can be freely chosen

- Vertical cans input and output, which can be connected to automatic seamer operation

- Central lubricating system underside, making maintenance easy.

- Hard chromium plating on the interfaces with cans, ensuring abrasion resistance

- An inverter makes speed adjustment easy

- Equipped with a shield to ensure the safety of machines and operators

| Machine type | ST-B55A | ST-B84 | ST-B82L | ||

| Working Head | Flanging 4H/ Beading 6H | Flanging 6H/ Beading 9H | | Flanging head:3H, Double Roller beading head:5H | Flanging head: 6H, double rollers for beading 8H, Seaming 6H |

| Range of can dia | 211D-401D | 401D-800D | 211D-401D | ||

| Range of can height | 80-130 mm | 80-180 mm | 80-130 mm | 130-260mm | 70-130 mm |

| Capacity per minute | Up to 300 cans/min(depend on can size) | Up to 200 cans/min(depend on can size) | Up to 350 cans/min(depend on can size) | Up to 150 cans/min(depend on can size) | Up to 350 cans/min(depend on can size) |

| Horse power required | 3.7+0.75+0.18KW | 7.5+1.5+0.4+0.18KW | 5.5+0.75+0.18KW | ||

| Floor space &overall height | 2700×1550×1350 mm | 2700×1550×1450 mm | 2700×1550×1350 mm | 3400×2300×2600 mm | 3200×2000×1850 mm |

| Net weight | About 4000 kgs | About 4500 kgs | About 5000 kgs | About 8500 kgs | About 7000 kgs |

| Height of input station | 820 mm | 920 mm | 820 mm | 937 mm | 910 mm |

| Lubricate | Central lubricating system (underside)&manual lubricate(upside) | Central lubricating system(underside)&manual lubricate(upside) | Central lubricating system(underside)&manual lubricate(upside) | ||

| Speed control | Inverter | Inverter | Inverter | ||

| Beading depth | < 1.0mm | ≤1.8mm | < 1.0mm | ||

Other Products