- Home

- Products

- Can Body Making Machine

- Flanger/Necker/Beader

- Automatic Vertical Necker with Flanger Machine

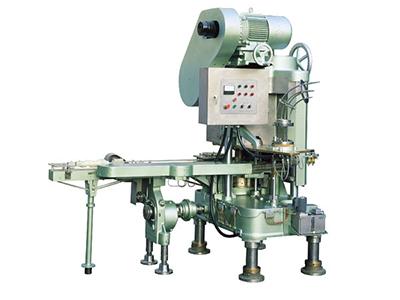

Automatic Vertical Necker with Flanger Machine

Automatic vertical neckers with flanger machines are used for the necking and flanging of large 3-piece cans to form various shapes. STWMF supplies a variety of independent neckers and flangers, as well as combination machines. We manufacture 2-stage, 3-stage, and 4-stage neckers, as well as a variety of necker dies.

Advantages- Central lubricating system underside: The main drive gears are located on the machine body, making it easy to install the automatic oil spray lubricating machine inside the machine for later maintenance.

- Hard chromium plating on the interfaces with cans, thus preventing abrasion

- With the use of inverters, a stepless speed adjustment is achieved for the perfect match between former and later processes.

- Equipped with shield to ensure the safety of machines and operators

The following are three types of neckers with beaders we have manufactured for customers to choose from. If these don’t meet your needs, simple share your requirements and we will adjust equipment based on your requirements.

Parameters| Machine type | ST-B105N | ST-B105 | ST-B31V4N |

| Necking stage | 2-stage | 3-stage | 4-stage |

| Working Head | 6H/6H/6H | 6H/6H/6H/6H | 6H/6H/6H/6H |

| Range of can dia | 202D-401D | 202D-401D | 202D-401D |

| Range of can height | 70-180 mm | 70-180 mm | 70-180 mm |

| Capacity per minute | Up to 300 cans/min(depend on can size) | Up to 500 cans/min(depend on can size) | Up to 300 cans/min(depend on can size) |

| Horse power required | 7.5+0.37+0.18KW | 7.5+0.37+0.18KW | 7.5+0.37+0.18KW |

| Compress air Required | 3kgf/cm² × 100L/min | 3kgf/cm² × 100L/min | 3kgf/cm² × 100L/min |

| Floor space &overall height | 3000×2000×1900 mm | 3500×2000×2000 mm | 3500×2000×2000 mm |

| Net weight | About 6500 kgs | About 8000 kgs | About 8000 kgs |

| Height of input station | 795 mm | 795 mm | 793 mm |

| Lubricate | Central lubricating system(underside)& manual lubrication(upside) | Central lubricating system(underside)& manual lubrication(upside) | Central lubricating system(underside)& manual lubrication(upside) |

| Speed control | Inventer | Inventer | Inventer |

Other Products